Quality Control Checkpoints

1. The sales department shall negotiate with customers on details such as product drawings and functions before signing the order.

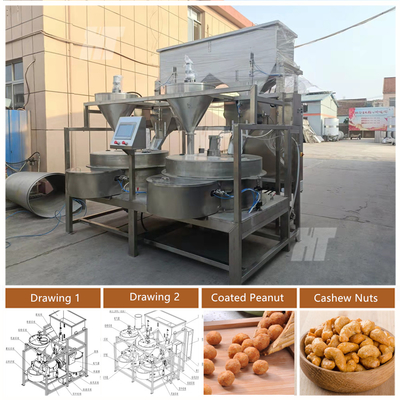

2. The design department need design and confirm the drawing according to customer before production, also need confirm the composition and quantity of each component in accordance with the order drawings.

3. All purchased materials, including stainless steel tubes, sheet metal, machined parts and other accessories, shall be inspected and counted upon delivery to the factory.

4. During the production process, the production department shall conduct quality checks to ensure the quality of welded sheet metal and other products. The person in charge shall carry out regular spot checks and rectify any identified problems in a timely manner.

5. All components shall be Welding and assembled and cleaned strictly in accordance with the drawings.

6. Conduct commissioning in conjunction with the matching of power distribution cabinets, electrical and gas systems, etc., and rectify any detected problems promptly.

7. Prepare materials for the actual operation debugging of the finished product, test its functions comprehensively; if any problems are found, coordinate with the production department and design department to make timely adjustments and re-commissioning.

8. Conduct cleaning and packaging after the completion of commissioning. Disassemble all components and package them in a standardized and uniform manner and arrange the shipment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!