Yantai XT Machinery | Professional OEM/ODM One-Stop Service for Peanut Processing Machinery

As a technology-driven manufacturing enterprise with over ten years of experience in the peanut processing machinery field, Yantai XT Machinery leverages its mature R&D system, standardized production capabilities, and comprehensive quality control advantages to provide professional OEM/ODM integrated services to global customers. From customized development to mass production and delivery, we empower our clients throughout the entire process, helping them quickly create exclusive branded equipment that meets market demands.

I. Service Positioning and Core Scope

We focus on the equipment needs of the entire peanut processing industry chain, providing both ODM customized development and OEM contract manufacturing services, covering various peanut and nut processing equipment:

ODM Core Services:

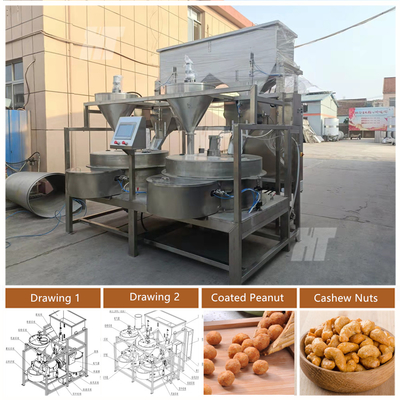

For clients without mature solutions, we provide full-chain development services from demand definition to finished product delivery, covering customized R&D of a full range of equipment, including Peanut Butter Production Line, Blanched Peanut Processing Plant, Continuous Nuts Roaster, Automatic Nuts Coating Machine, Frying Coated Peanut Processing Plant , Roasted Peanut Crushing Line .etc.

OEM Specialized Services:

For clients with existing technical drawings or mature designs, we provide standardized contract manufacturing, supporting brand labeling, packaging customization, and personalized configuration adjustments, adapting to both small-batch trial production and large-scale mass production needs.

II. Core Service Content

(I) ODM Full-Chain Customized Development

1. In-depth Demand Analysis: Our sales and technical teams jointly conduct research to accurately capture customer capacity requirements (50-5000kg/h), workshop layout dimensions, raw material characteristics (Peanut origin, variety, size, hulling rate, half-kernel rate), and process preferences, and produce a "Customized Demand Analysis Report."

2. Systematic Solution Design: Our team of senior engineers, based on over ten years of process experience, completes equipment structure design, circuit configuration, and process optimization, providing 3D drawings and technical parameter lists, specifying equipment materials (food-grade stainless steel), energy consumption standards, and core performance indicators.

3. Prototype Iteration and Verification: We quickly complete prototype sampling and performance testing, simulate the customer's actual production scenario to adjust parameters, invite customers to participate in acceptance testing, and optimize equipment ease of operation and running stability based on feedback to ensure the feasibility of the solution.

4. Mass Production and Delivery Guarantee: After verifying the feasibility of the production process through small-batch trial production, we initiate large-scale production, synchronize production progress throughout the process, and finally deliver finished equipment and complete technical documentation that meets design standards.

(II) OEM Standardized Manufacturing Services

1. Precise Production Matching: We strictly adhere to the technical drawings and quality standards provided by our clients. Leveraging our professional workshops for sheet metal processing, precision welding, and automated assembly, we achieve stringent requirements for component processing accuracy of ±0.02mm, ensuring the consistency of every piece of equipment.

2. Flexible Brand Customization: We support laser engraving of customer brand logos, adjustments to equipment appearance and color schemes, and customized packaging, strictly protecting the standardization and uniqueness of our clients' brand identities.

3. Short-Cycle Response and Delivery: With our mature supply chain system and lean manufacturing management, we achieve delivery within 7-15 days for small-batch orders and within 30 days for large-batch orders, meeting our clients' needs for rapid market entry.

III. Exclusive Cooperation Advantages

1. Strong Technical Support: Our engineering team, with over 10 years of industry experience, deeply understands the pain points of peanut processing technology and can quickly overcome customized technical challenges such as low-damage peeling, uniform roasting, and energy-saving frying. The core performance of our equipment meets international standards.

2. Robust Production Capacity: Equipped with standardized production workshops and precision processing equipment, our monthly production capacity can reach over 50 sets of various production lines. We can handle trial orders of 1-2 sets for small businesses and also meet the bulk demand of over 50 sets for large groups, flexibly adapting to order fluctuations.

3. Zero Quality Deviation: A comprehensive quality control system runs throughout the entire process – the procurement department strictly selects high-quality raw materials such as 304 stainless steel, the production department conducts process inspections, and the QA department performs 12 factory tests, including load testing and life cycle testing, to ensure a 100% pass rate.

4. Optimized Cost Control: Through large-scale procurement to reduce raw material costs and lean manufacturing to minimize losses, we can help customers reduce equipment customization costs by 10%-15% compared to the industry average, enhancing their competitiveness.

IV. Standardized Cooperation Process

- Demand Matching: Our sales team responds within 12 hours, clarifying capacity, process, budget, and brand requirements, and establishing a dedicated service file;

- Solution Output: The technical department provides a preliminary design plan and quotation within 3 working days, detailing materials, processing, testing, and other costs;

- Prototype Confirmation: After signing the agreement, the prototype is completed within 10-15 days, and customer acceptance is organized, followed by the issuance of a "Prototype Test Report";

- Mass Production Execution: Production is organized according to the confirmed plan, with production progress updated every 5 working days;

- Quality Inspection and Delivery: After completing factory testing, a "Quality Certificate" is provided, and we assist customers with logistics;

- After-Sales Support: We provide installation and commissioning, operation training, and a 1-year warranty service, with 24-hour technical support.

V. Cooperation and Guarantee System

- Intellectual Property Protection: Confidentiality agreements are signed, and customer-specific solutions, technical drawings, and brand information are managed with full encryption to prevent leakage or reuse;

- Technical Documentation Support: Complete technical documentation is provided upon delivery, including operation manuals, maintenance guides, and parts drawings, for convenient future operation and maintenance;

- Global Market Adaptation: We can assist with obtaining international certifications such as CE, and the equipment circuitry supports multi-voltage customization (220V/380V) to adapt to different national production standards;

- Lifetime Technical Support: After the warranty period, we provide continuous parts supply and upgrade services to help customers ensure the long-term stable operation of their equipment.

From single equipment customization to complete line solutions, Yantai XT Machinery creates value for customers with its professional capabilities. We have provided OEM/ODM services to brands in over 30 countries and regions, including Europe, America, and Southeast Asia, and have gained widespread industry recognition. If you need a customized solution, please feel free to contact us!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!